Since the mobile phone entered the era of smart phones from the era of feature phones, it has catalyzed the boom of another mobile phone industry, that is, mobile phone protective shells. In the early days of smart phone development, mobile phone brand manufacturers were disdainful of designing and selling mobile phone protective cases. However, with the development of smart phones, the screen size of mobile phones is getting larger and larger, which means that the cost of screens in mobile phones is getting higher and higher. The screen of mobile phones has been changed from PC and acrylic materials to glass materials. With qualitative improvement, its fragility is also greatly improved. Headed by Apple, a large number of manufacturers have begun to design and sell mobile phone protective cases by themselves, while spared no effort to improve the anti-fall capability of protective glass. Because the cost of a protective shell is relatively small compared to a screen module.

It can be said that the main function of the mobile phone protective shell is to protect the mobile phone, prevent hard objects from leaving scratches on the screen or body of the mobile phone, and cause the screen to break when it is accidentally dropped. What material is used for the mobile phone protective shell? Here we introduce to you.

1.silicone protective case

There are two types of silica gel materials, one is solid silica gel and the other is liquid silica gel. The two silicone molding processes are completely different. The solid silicone is hydraulically molded and the mold structure is simple. The liquid silicone is injection molded, which is suitable for two-color and more complex products.

The most famous silicone protective case is Apple’s liquid silicone protective case, which is bright in color and soft to the touch. In fact, the iPhone case is composed of two materials: a soft inner lining made of microfiber, and an outer layer wrapped by LSR (liquid silicone). Liquid silicone material features soft texture, strong resistance to stretching and reduction, but the only disadvantage is that it is easy to stick to dust, and it will turn yellow after using for a period of time, especially white silicone. But both reliability have been resolved. Before the liquid silicone is molded, the manufacturer will add a certain proportion of anti-yellowing agent to solve the yellowing. After the silicone is molded, a touch of oil is sprayed on the surface, which not only makes the protective shell feel more silky, but also effectively solves the problem of sticking to the surface of the protective shell.

However, the process of liquid silicone is complicated and involves mold design and silicone surface treatment. Therefore, it is not common to use liquid silicone as the protective shell material.

2.TPU protective shell

The second is TPU material, which is currently one of the most used materials for mobile phone protective cases. TPU (Thermoplasticpolyurethanes) is scientifically called thermoplastic polyurethane elastomer rubber. It has a wide range of hardness (60HA-85HD), abrasion resistance, oil resistance, transparency, good elasticity, etc. In particular, the abrasion resistance, impact resistance, aging resistance and shock absorption of TPU materials are much better than the silica gel introduced earlier material.

TPU material is used in the transparent case of iPhone XR, which sells for up to 320 yuan on Apple’s official website. It is made of highly transparent polycarbonate and flexible TPU material. The outer and inner surfaces of the protective shell have anti-scratch coatings. . The same two-color molding process is used. The lining structure is supported by transparent engineering plastic PC material, and the outer layer is evenly wrapped with a soft TPU material. This not only ensures that the structure will not be deformed, and the outsourced TPU provides a comfortable touch, but the disadvantage is that it is not as comfortable as the silicone material.

3.TPE protective shell

The third is TPE material, Thermoplastic Rubber (TPE) or TPR for short. It is a rubber with elasticity at normal temperature, and a type of elastomer that can be plasticized at high temperature; TPE material has good anti-slip property and good elastic touch, which can improve the touch of the product and enhance the grip. The market is also huge. But the only disadvantage of TPE material is that the material tastes great, while silicone and TPU are tasteless.

4.Leather protective shell

The fourth is the leather phone case, which can be said to be a more traditional material. The apple leather protective lining is also made of microfiber material as the structure and fastened elastic body, and then the leather is wrapped outside, so the surface of the mobile phone case is soft to the touch. And the phone case made of this material will form a natural texture and luster over time. However, because leather materials and processing costs are high, the proportion of leather mobile phone protective cases is limited.

5.Wooden protective shell

Wooden mobile phone protective shell, wooden mobile phone protective shell, the main structure is still engineering plastic PC, the processed wood is attached to the PC structural parts. The wooden mobile phone protective shell only plays a decorative role in nature, and cannot really protect the mobile phone.

6.Kevlar protective shell

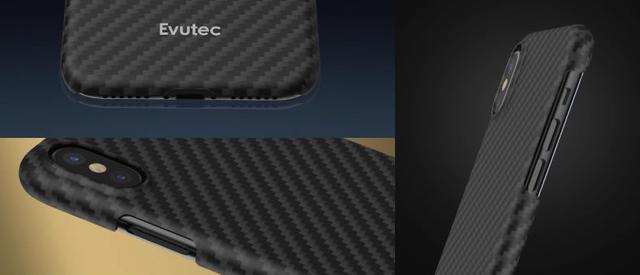

Kevlar material, also known as aramid fiber, that is, aromatic polyphthalamide fiber, the full name is “polyphthalamide”, English is Aramidfiber, which is made of aromatic compounds through polycondensation spinning synthetic fiber. Aramid fiber has good impact resistance and fatigue resistance, good dielectric and chemical stability, resistance to organic solvents, fuels, organic acids, and strong acids and alkalis at dilute concentrations, good resistance to inflection and processing. However, the cost of materials and processes is high.

The above are the most common materials on the mobile phone protective shell, of course, there are some less commonly used will not be listed. The most used is TPU material. Regardless of material cost and material characteristics, the process has unparalleled advantages of other materials, and it is also widely used in wearable products, such as smart watch straps.

It can also be seen from the introduction of the material of the mobile phone protective shell that a high-grade or a qualified protective cover must be composed of two materials. The lining is used as the structural part of the protective shell, with certain structural strength, toughness, and elasticity as the support. It can also ensure that the protective case fits tightly with the protection of the mobile phone. The material on the outer lining has silky soft feel, suitable damping, anti-yellowing, and hand sweat resistance. Therefore, there is no mobile phone case made of two materials, which is not a qualified phone case. What is the material of your phone case?

Please specify:Anime Phone Cases » Picking a phone case? It is better to start with the characteristics of the phone case material!